How to Choose a Sheet Metal Fabricator You Trust

- Find a long-standing company.

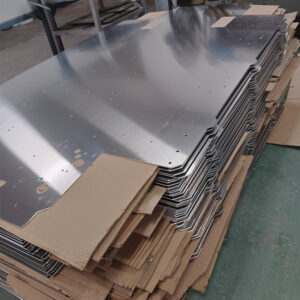

- Prioritize fabricators with the best equipment.

- Check the quality of the shop’s materials.

- Consider the company’s customer service record.

How to choose a custom sheet metal factory? Customized processing is a relatively common processing process nowadays. Because this processing process can design products according to the actual needs of customers, it has been well received by the majority of customers. However, many entrepreneurs who want to engage in this industry do not know how to choose a reliable processing plant. Here are some of the experience for you from custom metal box manufacturers

1. Look at the size of the factory: in general, small workshops do not have the strength of the factory and there is no need to choose.

2. Look at the production equipment: the good or bad equipment directly affects the quality and efficiency of the product.

3. look at the technical strength, whether the process is perfect and reasonable, mature and stable.

4. to see the service attitude and the after-sales maintenance capability.

5. to examine whether the manufacturer has its own production workshop or warehouse (if not, it means that it is only a simple assembly).

custom sheet metal boxes First, master the manufacturer’s production and manufacturing process.

As professional sheet metal fabricators not only have rich manufacturing certificates, but also in the actual production, processing and production of products, using their own process advantages, they can better ensure the timeliness and quality of the product production process, while integrating the customer’s use problems, constantly improving and designing products, mastering the actual production technology, improving the precision of metal fabrication, and meeting the application regulations of today’s users.

Second, technical professional manufacturers manipulate costs of custom sheet metal boxes

Now in the choice of metal material laser cutting processing products, you can also see a variety of different models and specifications, especially in the manufacture and manufacturing of new products, sheet metal processing plant must have a certain basic overall strength to design and develop new products, is the manufacturer of new technologies and machinery and equipment to improve the effect and product accuracy, reduce residual, so that product costs are reasonable operation, reflecting the professional technology manufacturer’s own production advantages.

Please contact JIATONG sheet metal box manufacturers to learn more about custom aluminum box.