Sheet metal box and steel box are both types of metal boxes, but they are different.

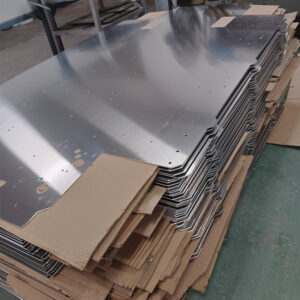

Sheet metal is a thin, flat metal sheet that can be made from a variety of metals, including aluminum, copper, brass, and stainless steel. Sheet metal is usually less than 6mm thick and can be easily cut, bent, and formed using a variety of metalworking techniques. Sheet metal boxes are typically made by bending and welding the sheet metal into the desired shape, using techniques such as spot welding, MIG or TIG welding, or riveting to join the panels together. Sheet metal box often used for applications that require light weight, flexibility, or low cost.

Steel, on the other hand, is a more rigid and durable metal than sheet metal, made primarily from iron and carbon. Steel can be made into a variety of shapes and sizes, including sheets, rods, bars, and tubes. Custom steel box is typically made by cutting and welding the steel into the desired shape, using techniques such as MIG or TIG welding to join the panels together. Steel boxes are often used for applications that require high strength, durability, and resistance to impact or abrasion.Clike here to contact sheet metal box manufacturers for further details.