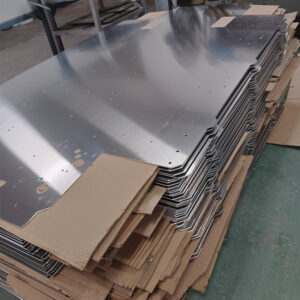

The most commonly used materials for sheet metal operations including:

Steel: Steel is a multifunctional and durable material that is commonly used for sheet metal operations. It’s available in various grades and thicknesses, making it suitable for a wide range of applications.

Aluminum: Aluminum is lightweight, corrosion-resistant, and has good strength-to-weight ratio, making it a popular material for sheet metal operations. It’s commonly used in the aerospace, automotive, and construction industries.

Stainless steel: Stainless steel is a corrosion-resistant material that’s commonly used for sheet metal operations that require high strength and durability. It’s often used in food processing, medical, and chemical industries.

The choice of material for sheet metal operations depends on the specific requirements of the application, such as strength, durability, conductivity, and corrosion resistance. It’s important to select the appropriate material to ensure that the finished product meets the desired specifications and performs as intended.at the same time,to choose the right sheet metal supplier is important .

Custom Metal Box Manufacturers | Custom Sheet Metal Enclosures | Custom Aluminum Box | Custom Sheet Metal Boxes | Custom Metal Boxes | Sheet Metal Supplier | Steel Box Manufacturers | Sheet Metal Box Manufacturers | Custom Made Metal Boxes | China Sheet Metal Manufacturer | Outdoor Vending Machine Enclosures | Equipment Enclosures | Machinery Enclosures | Machine Enclosure | Machine Enclosures | Industrial Machine Enclosures | Metal Enclosures for Electronics | EV Charger Outdoor Enclosure | Outdoor EV Charger Enclosure | EV Charger Enclosure