MFG Guide

Customized sheet metal manufacturing

The advantages of sheet metal manufacturing can be summarized as follows: high precision, high automation, fast speed, simple and convenient operation, high efficiency. High power density of…

Space problem of sheet metal server cabinet

The “U” of the server we usually call is a unit that represents the external size of the server. It is an abbreviation of unit, which is…

New energy battery aluminum sheet metal shell

The aluminum shell of the battery has high specific strength, specific modulus, fracture toughness, fatigue strength and corrosion resistance stability. Because aluminum alloy materials have the characteristics…

Beverage bottle recycling machine shell

The beverage bottle recycling machine is an environmental protection self-service terminal customized and developed to benefit mankind, create a green life, and focus on the environmental protection…

How to deal with burrs when cutting 2.5mm carbon steel plate by laser cutting?

In this case, the lens may be dirty. At first, the lens is clean, so there is no problem cutting it out. The back lens is dirty,…

Shell design of low voltage distribution cabinet

Strong applicability, wide selection of main components, and many domestic and imported brand products can be interchanged. Good installation flexibility. In the future, even if the competent…

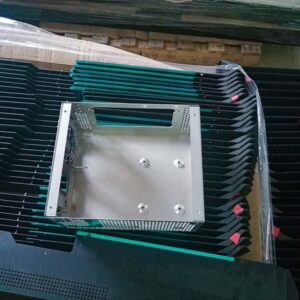

Metal plate chassis shell processing

Before processing the house, workers need to know the processing scope. In general, sheet metal processing materials such as copper products, galvanized steel and stainless steel can…

Three-dimensional five axis laser cutting machine for hot formed parts

The hot forming three-dimensional five axis laser cutting machine is a high-end machine tool designed for the processing of automobile parts. The product is oriented to the…

Precautions for spraying of double process finish paint

Dual process topcoat refers to a spraying system in which two different coatings are sprayed to form a complete topcoat. Usually, the paint is sprayed first, and…

Stamping die terminology

Blanking Blanking is a stamping process in which a part of materials or process parts are separated from another part of materials, work (process) parts or waste…