Technology News

Mechanical method for treating stainless steel rust spots

Blast cleaning, shot blasting with glass or ceramic particles, annihilation, brushing and polishing. It is possible to remove contamination caused by previously removed, polished or annihilated materials…

Analysis of heat treatment process

It can simulate various quenching, annealing, tempering and other heat treatment processes to obtain the temperature distribution, deformation, hardness, residual stress and other results of parts, quickly…

Methods to prevent corrosion of sheet metal shell

In the production of sheet metal shell, sometimes no matter what material we use, the sheet metal shell may be corroded after long-term use due to the…

How to determine the bending sequence of sheet metal bending?

General bending sequence Short side first and then long side: Generally speaking, when there are bends on all four sides, the short side first and then the…

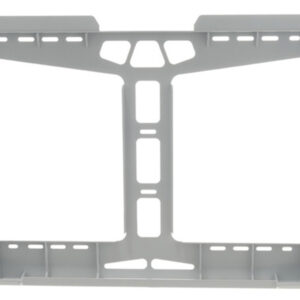

Process of sheet metal parts from making to forming

1、 Blanking. After the drawing is successful, the blanking methods shall be determined according to the expansion drawing, batch gap and technical requirements, including laser, CNC punch,…

Four basic cold processing links to optimize sheet metal design

Generally, sheet metal parts have obvious advantages in strength, weight and cost, and have better point-to-point performance than traditional parts. Therefore, up to now, sheet metal parts…

Sheet metal die classification

Classification according to process properties A die that separates material along a closed or open contour. Such as blanking die, punching die, cutting die, cutting die, trimming…

Fiber laser cutting machine

China has gradually become an international processing and manufacturing center, and the demand for metal processing is increasing. Generally speaking, the electrical control box and machine shell…

Common problems in bending process

Sheet metal processing manufacturers generally have many kinds of processes, and bending process is one of them, which is often used. Problems are inevitable in this processing…

Requirements for painting and welding

Painting requirements Rust, scale, grease, dust, soil, salt and dirt must be removed from the surface of all steel parts to be painted before painting. Before…