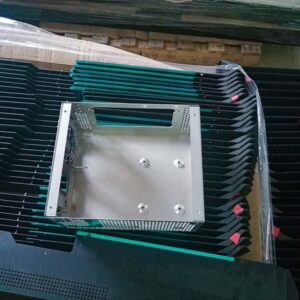

china sheet metal

Three-dimensional five axis laser cutting machine for hot formed parts

The hot forming three-dimensional five axis laser cutting machine is a high-end machine tool designed for the processing of automobile parts. The product is oriented to the…

Bending structure processing technology of sheet metal

The bending structure processing technology of sheet metal is a difficult point in the sheet metal processing technology. Its processing has a lot of data requirements, and…

Multi wavelength hybrid welding and its advantages

Multi wavelength hybrid welding is the first welding process of LY laser, which makes the axes of the two lasers coincide in space by superimposing two lasers…

Precautions for spraying of double process finish paint

Dual process topcoat refers to a spraying system in which two different coatings are sprayed to form a complete topcoat. Usually, the paint is sprayed first, and…

Stamping die terminology

Blanking Blanking is a stamping process in which a part of materials or process parts are separated from another part of materials, work (process) parts or waste…

Unfolding a sheet metal assembly

The actual unfolding length of a sheet metal part is often the sum of its straight-line length and neutral layer length. For the calculation of the length…

Laser drilling technology

Laser drilling technology is the earliest practical laser technology in laser material processing technology. In the sheet metal workshop, pulse laser is generally used for laser drilling,…

Mechanical method for treating stainless steel rust spots

Blast cleaning, shot blasting with glass or ceramic particles, annihilation, brushing and polishing. It is possible to remove contamination caused by previously removed, polished or annihilated materials…

Features of laser cutting machine 6025

Be able to cut various figures on the plane plate; High precision, fast speed, narrow cutting seam, minimum heat affected zone, smooth cutting surface without burr, minimal…

Analysis of heat treatment process

It can simulate various quenching, annealing, tempering and other heat treatment processes to obtain the temperature distribution, deformation, hardness, residual stress and other results of parts, quickly…