Technology News

How to do the Housing Design of Machinery and Equipment?

Mechanical equipment shell is installed on the outside of the equipment shield, is used to prevent people from entering the danger zone, and exposed high-speed moving or…

How to Deal with Heat Deformation in Sheet Metal Shell Processing?

Nowadays, sheet metal shell processing is a very common metal processing method, which also includes many processing processes, and heat deformation is one of them. The following…

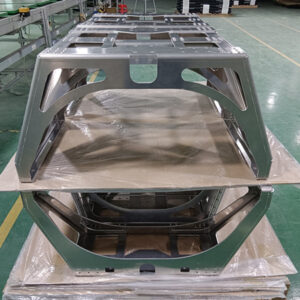

Sheet Metal Processing Semiconductor Equipment Racks

With the development of science and technology, the iteration of electronic products is getting faster and faster, and as the semiconductor of electronic products, its manufacturing and…

How should the Small Heat Dissipation Hole be Processed?

The development of the sheet metal processing industry is in increasing demand, which is also attributed to the rapid development of society and the popularity of high-tech…

What are the Different Types of Powder Coating?

According to the performance, coating thickness and use of different coatings are divided into: primer, antirust and anti-corrosion coatings and conductive shielding coatings, etc. Primer: mainly made…

What are the Causes of Custom Sheet Metal Rusting?

1. When pickling passivation, the acid at the seam is not neutralized or neutralized incompletely, and the pickling phosphate becomes a skin film incompletely and rusts easily….

What is the Process of the Customized Aluminum Box?

Custom aluminum profiles cutting:Due to the conventional size of aluminum boxes and their design needs, to be made of different sizes and angles of different aluminum profiles…

What Benefits can the Aluminum Box Bring to the Product?

First, the custom aluminum box has a very good isolation role, its sealing is much higher than other packaging materials, moisture-proof, waterproof, dustproof, anti-corrosion. Second, the surface…

What are the Common Applications of Sheet Metal?

Owing to its strength, durability, versatility and cost effectiveness, sheet metal is used in a wide range of industries. The following are some common applications for sheet…

What is the Sheet Metal Material?

The most commonly used materials for sheet metal operations including: Steel: Steel is a multifunctional and durable material that is commonly used for sheet metal operations. It’s…